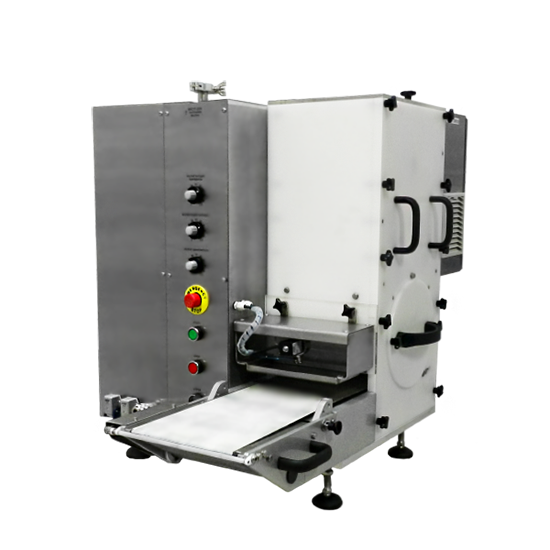

AUTOMATIC FORMING MACHINE RFM-200

FOR PRODUCING THE PRODUCTS OF PAST BASED (FRUIT) MASS

In production the product, you can use various paste based (fruit) mass, for example, such as marzipan, creamy fudge, toffee, hematogen, soft candied roasted nuts, coconut flakes with syrup, nougat, protein masses and different fruit masses with various additives (date paste, dried apricots, dried French plum, mango, cherry, etc.) it all depends on your imagination and needs, the main thing is that the resulting mass has the main properties - stickiness and uniformity.

Specifications

- Working width: 200 mm

- Roller Diameter: 250 mm

- Capacity: up to 5400 bars / hour *

- Energy Efficiency Class: IE 3

- Weight: 190 kg

- Electric power: 380 V, 50 Hz, 3 phases

- Dimensions LxWxH: 900х780х770 mm

- * When calculating a bar size 95*30*15 mm

Advantages

Compact and high capacity of the forming machine RFM-200

Quick change of formats, and wide range of different formats and individual development for the client's product

A wide range of masses for forming

Easy service, the ability to integrate into an existing line

The ability to provide equipment for lease (for testing at the customer's enterprise)

Staff training and equipment starting are included

Logistic support (air, railway, car, sea)

Use of quality components

The technological process of work the forming machine RFM-200

Forming machine for cereal mass MMC-200 is very easy to operate and service. You will no need large production areas and huge lines. Despite its small size, the forming machine MMC-200 has capacity up to 5 400 bars per hour, with a working width of 200 mm.

The prepared mass (fruit paste (or any other homogeneous, paste based product) mixed with various additions (crushed nuts, protein, rice balls etc.) is loaded into the hopper of the forming machine manually or automatically using a transport system. Special feeding shafts in the hopper of the forming machine fill the cells in the forming roll by paste based mass. Cells are made individually for each customer based on the size and shape of the final product.

Thus, the forming machine RFM-200 works without scraps and defects. Precise of the speed control of the feeding shafts and the forming roll allows you to customize the operation of the forming machine for each of mass, which allows you to produce a large assortment of paste based masses with one forming machine. Experiment, find new combinations of taste and benefit, because the compositions of fruit masses can be a great many.

Next, the already formed product enters to the belt of the transport system of the forming machine. Thanks to the integrated transport system, the finished product can transferred to the enrobing or packaging machine.

The technological process of the automatic line

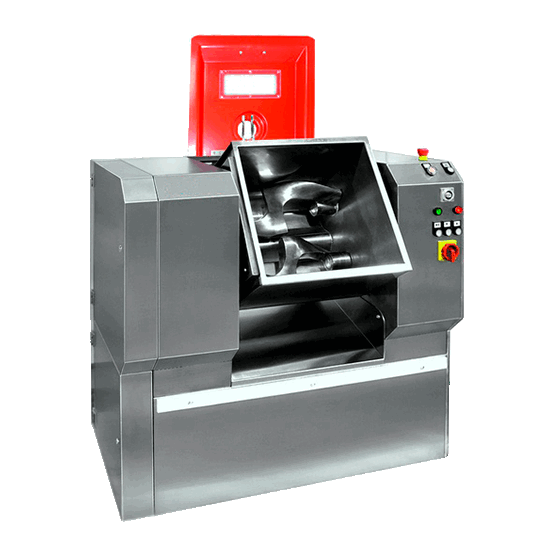

Step 1. Mixing the components. Fruit paste (or any other homogeneous, paste based product) and various additions (crushed nuts, protein, rice balls etc.) in accordance with the proportions of the formulation are loaded into the mixer MSW-80. Maked the mixing process. The resulting mass is unloaded and fed into the hopper of the forming machine for paste based (fruit) mass RFM-200 using a transport system or manually.

Step 2. Forming. After loading the mass into the hopper of the forming machine RFM-200, maked the forming process and the product of the final form for the next process step according to the technology enters the machine conveyor belt. It can be: cooling (if required to save the mass in shape); coating with chocolate or yogurt glaze (the whole product or only the bottom); heat treatment (on trays in a convection-type oven or by conveyor into a tunnel-type oven).

Step 3. Cooling. If the mass requires cooling for further work, then the product after the conveyor belt of the forming machine goes to the conveyor of the cooling tunnel SW-CT 200, the working length is 10 m.

Step 4. Enrobing. If the product according to the technology needs to be enrobed with chocolate or any other glaze, then after the cooling tunnel or immediately after the forming machine RFM-200, the product enters the mesh tape of the SW-ET 200 enrobing machine, where the product is completely enrobing with chocolate or glaze or only the bottom of the product.

Step 5. Cooling. After the enrobing machine SW-ET 200, the product must be cooled. For this is used the cooling tunnel SW-CT 200 , the working length 10 m.

Step 6. Packing. Packing. After all the processes according to the technology are finished, the product can be packaged. The most popular type of packing for this kind of product is flowpack packaging. To automate the packaging process, as well as to increase the speed of packaging, is used the automatic packing machine PMW-250 with automatic feeders, which align the product from the production line to one stream. The packed product is ready for sale.

Pictures

Contacts

-

Russia, Stavropol Territory, Nevinnomyssk, st. Nizyaeva, 41

- TEL. +7 (86554) 9-53-17 EXT. 500/504/104/501/506

- info@sweetstech.com