Specifications

Using for: casting chocolate products

Power: 4 kW

Dimensions LxWxH: 1680x1000x1700 mm

Capacity: up to 250 kg/h

Manufacturer: Sweets Technologies, Russia

About

The bunkers are equipped with agitators driven by compressed air.

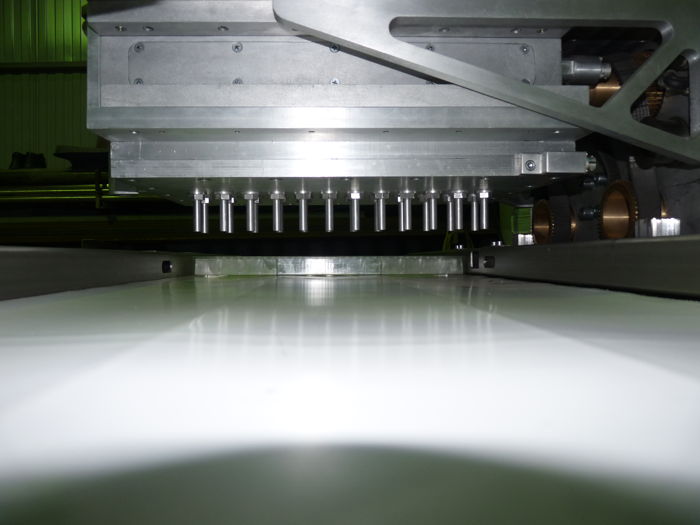

The casting method used in the depositor is based on the principle of a rotary pump with rotational and translational-return movement of the working bodies, which moves the liquid medium (chocolate mass and filling of the same viscosity) with periodic changes in the volumes filled by the chambers:

1. When the rotor or pair of rotors rotates (depending on the design of the machine), mass is sucked into the chambers of the rotor itself.

2. At the same time, the opening by the movement of the rotor and the movement of the comb of the channel for feeding mass.

3. At the same time, the opening by the movement of the rotor and the movement of the comb of the channel for feeding mass.

4. After opening the channel, the comb continues to move and continues to dispense the amount of mass specified from the operator panel.

5. Upon completion of the dosing of a given volume, with the parameters set on the operator panel (suction dose), the rotor and combs return to their original position at the same time (beginning of the cycle) and the cycle repeats. The program can also set preliminary and additional doses of the shell.

Positioning (interval) between the forms (0-100mm) is carried out by a pneumatic brake.

Cleaning the tape with a special scraper is provided, the removed mass is collected in a collecting container.

The process is controlled by a computer panel, a system of servomotors and controllers. The parameters are set manually or automatically provided that all parameters of the work processes are specified, up to 75 recipes (compositions) of the product are stored in the computer memory.